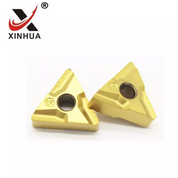

Cement carbide APMT1604 bits, which are changeable and typically indexable. Are use to APMT1604 machine steels, cast iron, high-temperature alloys, and nonferrous metals.

Read More-: What Are The Main Aspects Of VCGT160404?

For working on large or medium-sized projects, it is a great APMT1604 option. It adds hardness and wear resistance, particularly when cutting fast-moving metals or hard metals. Using chemical vapour deposition, a metal is ionise with electrical currents and deposited to the inserts as evaporated condensation, coating the tools. The tools carry out specific machining operations to create an infinite variety of tools, moulds, and parts.

It is frequently related to making holes with greater sizes. These procedures are normally carry out by spade-shaped carbide CCMT09T304 drill inserts to produce holes with precise diameter and depth. Typically triangular in shape, threaded carbide inserts have a notch on one side WNMG of each point. Fasteners, screws, and a variety of consumer goods are make using precision threading.

Read Also -: What Are The Uses Of Ccmt09t304 Carbide Turning Inserts?

It may feature slots that are intend to fit O-rings for secure sealing if it is turn into an automotive component, for instance. Asymmetrical Carbide Endmill features Ballnose Endmill including holes, slots, pockets, and 3D shapes are produce by this process.

Typically, the workpiece does not move but rather the carbide cutting tool. With the use of multiple-point carbide insert cutting tools, contoured surfaces can be shaped into the holes, grooves, threads, and tapers that are produced during turning.

Keywords-:

APMT1604 | CCMT09T304 | TNMG | Ball Endmill | Ballnose Endmill | Carbide Endmill | End Mill Bits | TNGG | VCGT160404 | WNMG.