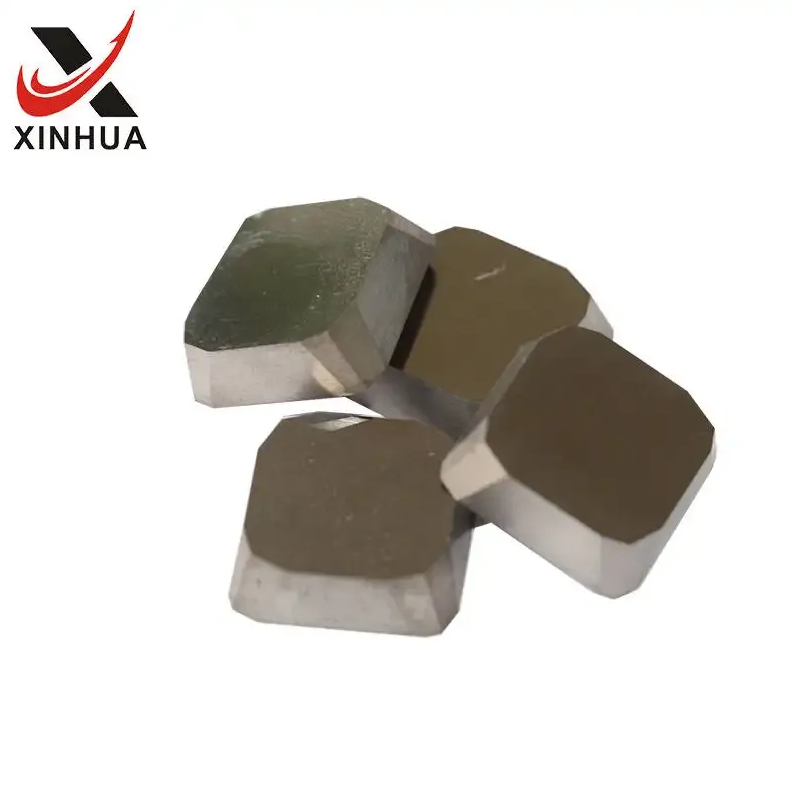

Carbide milling inserts remove material from a workpiece using milling machines. These inserts can tolerate high temperatures and pressures because they are made of tungsten carbide, a rugged and durable material. There are various shapes and sizes of carbide inserts, and they are designed to provide high precision and accuracy when cutting.

Uses of Carbide Milling Inserts

Various milling operations can be performed with carbide inserts, including face milling, slot milling, and shoulder milling. These tools aim to remove material from a workpiece to create flat surfaces, slots, pockets, and other shapes. Inserts made from carbide are also used in high-speed milling operations, where the tool rotates at high speeds to remove material quickly.

Industry applications for carbide milling inserts include:

- Automotive Manufacturing: A carbide milling insert is used in the automotive industry to manufacture engine blocks, cylinder heads, and other components. They are also used to produce brake discs, wheel hubs, and other parts that require precise milling.

- Aerospace Manufacturing: The aerospace industry uses carbide milling inserts to produce engine parts, landing gear, and wing spars. Satellites and other space vehicles are also constructed with them.

- Medical Manufacturing: The medical industry uses a carbide milling insert to produce surgical instruments, implants, and other medical devices. Dental implants and prosthetics are also made from them.

Conclusion

The durability and versatility of a carbide milling insert & CNC Grooving Insert make them widely used in multiple industries. Machine operations such as milling, drilling, and turning are ideal for these inserts. Precision and accuracy are essential for high-quality products. Furthermore, they are resistant to wear and tear and can handle high-speed cutting operations. The use of a carbide milling insert is an excellent investment for any business that requires efficient machining.

Faqs:

What is the lifespan of milling inserts?

A carbide milling insert’s lifespan depends on several factors, including the type of material being machined, the cutting speed, and the feed rate. In general, they can last between several hundred and a few thousand hours.

Is it possible to sharpen milling inserts?

A specialized sharpening tool can be used to sharpen a carbide milling insert. It is generally recommended to replace dull inserts with new ones once the process requires precision and expertise.

Get to know more:-

Tungsten Carbide | VCGT160404 | Ballnose Endmill | APMT1604 | CCMT09T304 | Carbide Cermet Inserts | Carbide Turning Inserts | CNMG120408 | Solid Carbide Endmills | Tungsten Carbide Manufacturers