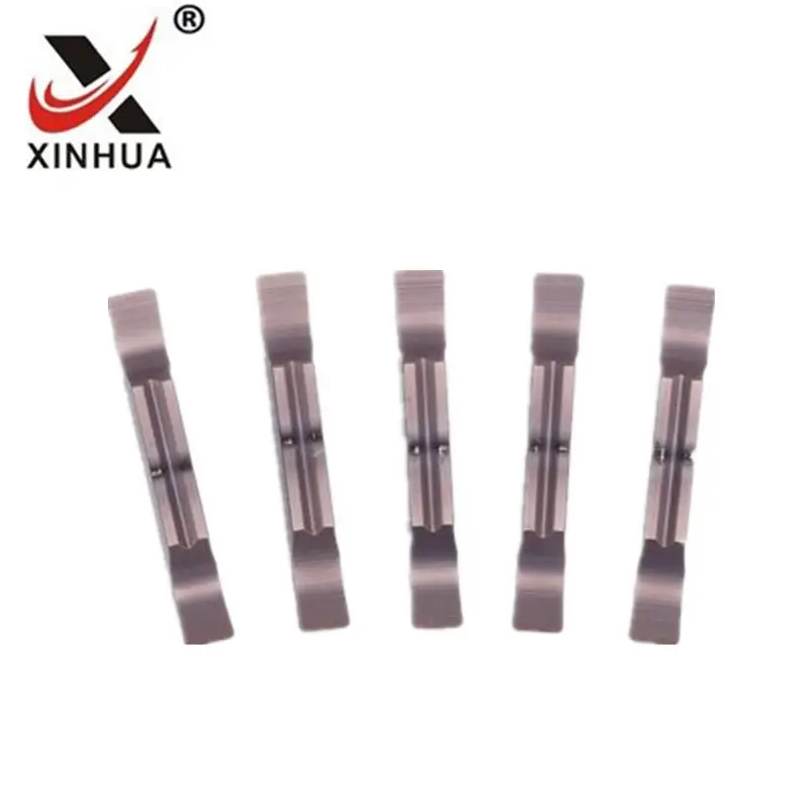

CNC grooving insert are highly specialized cutting tools that have become increasingly popular for precision machining operations. These inserts offer many advantages over other cutting tools, which make them ideal for high-precision machining applications.

Here are some of the key advantages of using CNC Grooving Insert:

- Versatility: CNC grooving inserts are highly versatile, making them suitable for various cutting applications. They can create deep grooves and slots, cut threads and internal features, and much more.

- Efficiency: CNC grooving inserts are designed to make deep cuts quickly and accurately, so they can reduce machining times and increase productivity. This can help manufacturers to meet tight deadlines and reduce production costs.

- Precision and accuracy: CNC grooving inserts are engineered to create tight tolerances and smooth finishes, which is essential for many machining applications. This ensures that the final product is high quality and meets the required specifications.

- Durability: CNC grooving inserts are made from high-quality materials designed to withstand the rigors of precision machining. They can maintain their cutting edge for longer, which reduces the need for frequent tool changes and increases overall efficiency.

- Cost-effectiveness: Despite their initial cost, CNC grooving inserts are cost-effective for precision machining operations. They can increase productivity, reduce machining times, and provide consistent results, ultimately leading to significant cost savings for manufacturers.

In conclusion, the advantages of CNC grooving inserts make them an essential tool for precision machining operations. Their versatility, efficiency, precision, durability, and cost-effectiveness make them an excellent choice for manufacturers who require high-quality cutting tools.

Also, you can contact us to buy TNMG160404-VF & Corner Radius Endmills.

FAQs:

Q: What types of materials can be machined using CNC grooving inserts?

A: CNC grooving inserts can cut various materials, including metals, plastics, composites, and more.

Q: How do I maintain and care for my CNC grooving inserts?

A: Regular cleaning, sharpening, and inspection are essential for the longevity and effectiveness of CNC grooving inserts. It is important to follow the manufacturer’s guidelines for cleaning and sharpening and to inspect the inserts for signs of wear or damage regularly.

Read more about us:-

Top Advantages Of CNC Milling Cutter Endmills

Contact us:-

Business Name: Zhuzhou Xinhua Cemented Carbide Industrial Co., Ltd.

Contact Person: Mina Tang

Address: No. 18, South Changjiang Rd, Tianyuan District, Zhuzhou City, Hunan Province, China

Country: China

City: Hunan

Skype: jacielyntt

Phone No.:+86-18153823027

Email id:carbidesales3@zxhcc.com

Website: https://www.xhcarbidetools.com/

Get to know more:-

CNC Milling Cutter Endmills | Square Endmills | Solid Carbide Endmills | CNC Carbide Inserts | Carbide Turning Inserts | Carbide Milling Inserts | Ball Nose Endmills